Concrete pavement progress cpp is the official magazine of the american concrete pavement association.

Portland cement association method for concrete pavement design.

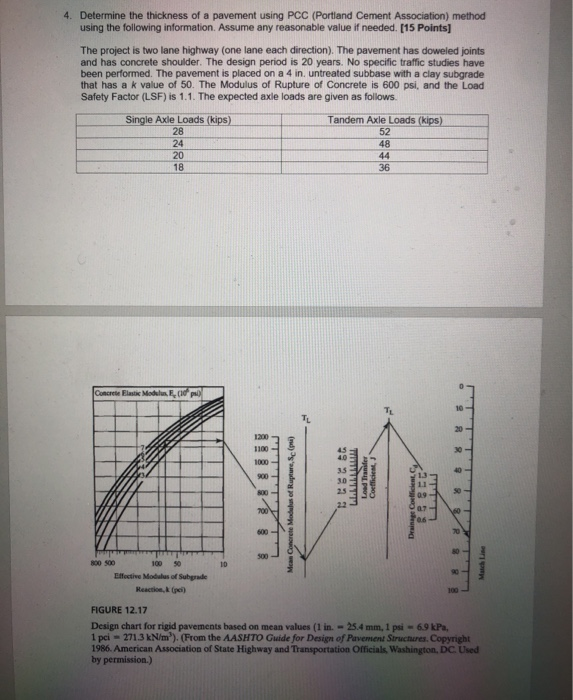

Effect of untreated subbase on k values 2.

The design approach used for rcc pavements is similar to the procedure used by the portland cement association for design of concrete airfield and heavy industrial pavements.

The portland cement association pca developed a new rigid pavement design method published in 1966.

Pca method of rigid pavement design.

The magazine is also available to all in flipbook format or to iphone ipad users through the itunes store.

Thus comparable designs of portland cement concrete and asphaltic.

200 massachusetts ave nw suite 200.

Design chart for composite concrete pavement monolithic with lean concrete lower layer.

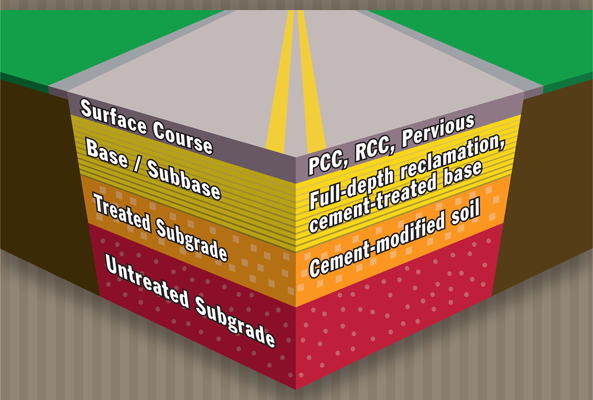

Utilized under concrete pavements.

This method was improved in 1984 to include a wider range of design considerations and pavement types.

The program was created for city county and consultant engineers academia or anyone.

5420 old orchard road.

Chicago 1952 c1951 page images at hathitrust portland cement association.

Concrete pavement design for roads and streets carrying all classes of traffic.

Analysis of tridems tables 1.

This design method determines the thickness for both.

For many years it was felt that construction procedures would not permit small increments of thicknesses of portland cement concrete pavements.

Design chart for composite concrete pavement lean concrete subbase b2.

Modulus of rupture versus compressive strength.

The american concrete pavement association has information on the design con struction and maintenance of these stabilized drainable bases available as a portland cement association pca publication titled cement treated permeable bases for heavy traffic concrete pavements is404p.

Concrete pavement inspector s manual.

In its printed format the magazine is circulated exclusively to 2 000 members and vips.

Cement association s method 7 or the method derived from the aasho road test 8.

Design k values for cement treated subbase 3.