The construction and concrete industries have so gravitated to polyethylene that new types of tools have been especially manufactured to assist n sealing joints via heat and pressure applications.

Polythene sheet for concrete.

Today most experts feel very strongly that engineered films designed specifically for use as vapor retarders should be used as vapor retarders.

Polythene sheet roadway expansion projects must fill a number of requirements to minimise environmental impact.

The sheet is generally supplied in rolls 4 m wide by 25 m long with a weight of 1 kilo metre.

The use of polythene sheet in construction projects.

Polythene sheet we are the leading manufacturer of ldpe sheet for construction and our product is made of good quality.

Although it may seem water tight this grade of material allows a lot of water vapor to pass through.

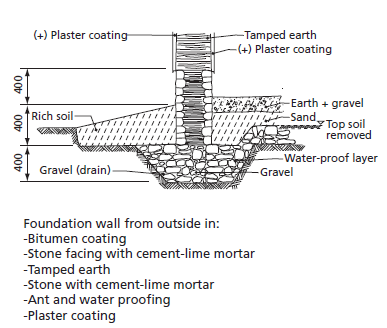

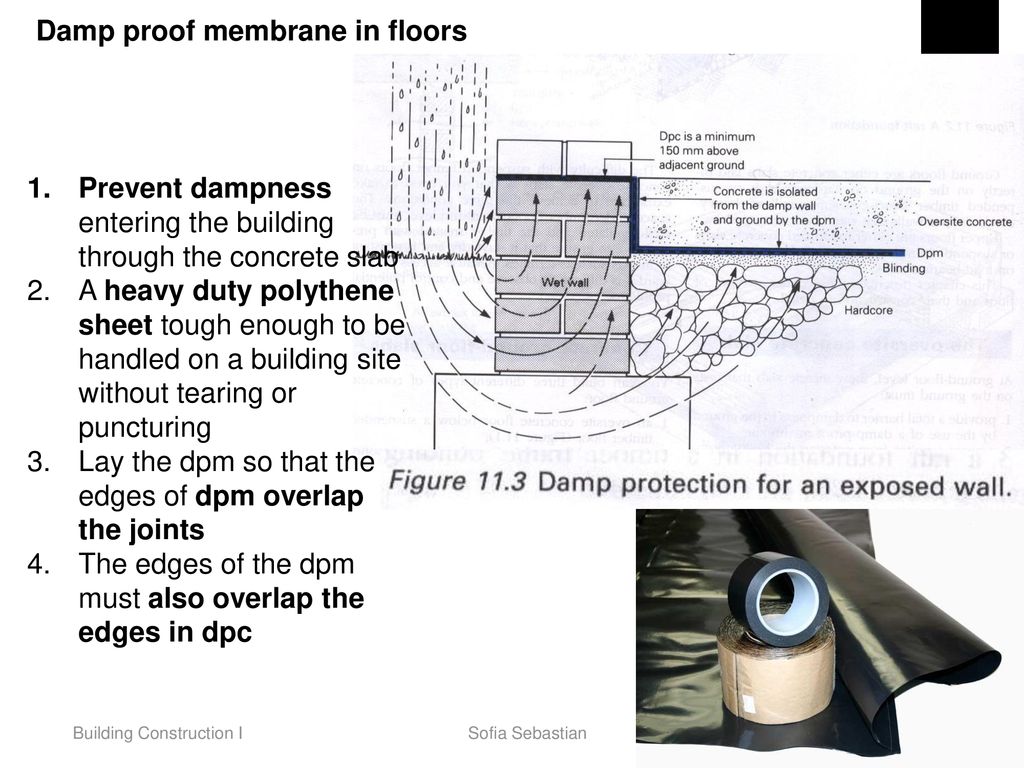

Polythene or polyethylene sheet is commonly used as a damp proof membrane with oversite concrete for all but severe conditions of dampness.

The general standard employed for the testing and verification of polythene sheets for use as a vapor barrier is the astm4397.

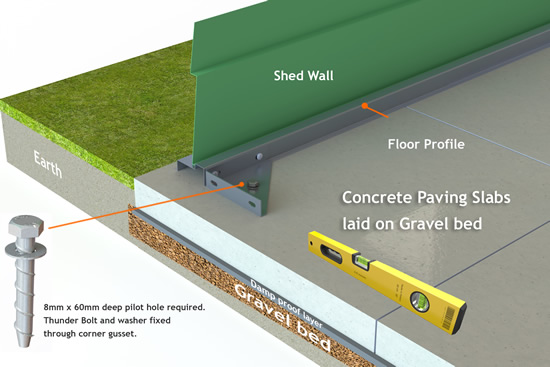

A concrete vapor barrier is simply a sheet of polyethylene plastic visqueen placed directly on top of the sub grade before the concrete floor or slab is poured to help keep moisture from the soil from passing up through the concrete.

So that concrete can take its own time for dry and avoids the possibilities of cracks and other damages.

These products are made.

As long as the polyethylene is protected from sunlight as it obviously is when it is installed under a concrete slab it should last indefinitely.

Construction poly sheets are mainly used for the construction sector.

Under slab vapor retarders play a very important role in retarding moisture from coming up through the concrete and into the structure.

It helps in separating the dry ground and the wet concrete.

Recently though research has shown that the old traditional layer of 6 mil visqueen polyethylene plastic under the slab is seldom effective for two main reasons.

And to increase the effectiveness of the film and reduce its environmental impact polyethylene sheets can be rolled and stored for future re use.

Whenever i have seen holes drilled through concrete slabs i have never noticed any degradation in the polyethylene layer.

Oversite concrete slabs employ a 1000 guage 250 microns polythene sheet laid underneath the concrete to prevent the moisture from being absorbed.

The sheet is supplied in rolls 4 m wide by 25 m long.

It is recommended that the sheet should be at least 1000 gauge.

It is recommended that the sheet should be at least 0 25 mm thick 1200 gauge.

Polyethylene sheeting under concrete slab.

6 mil plastic often gets damaged.